Product Description:

Snap-On Simplicity. Precision Measurement. Optimized for Larger Pipes.

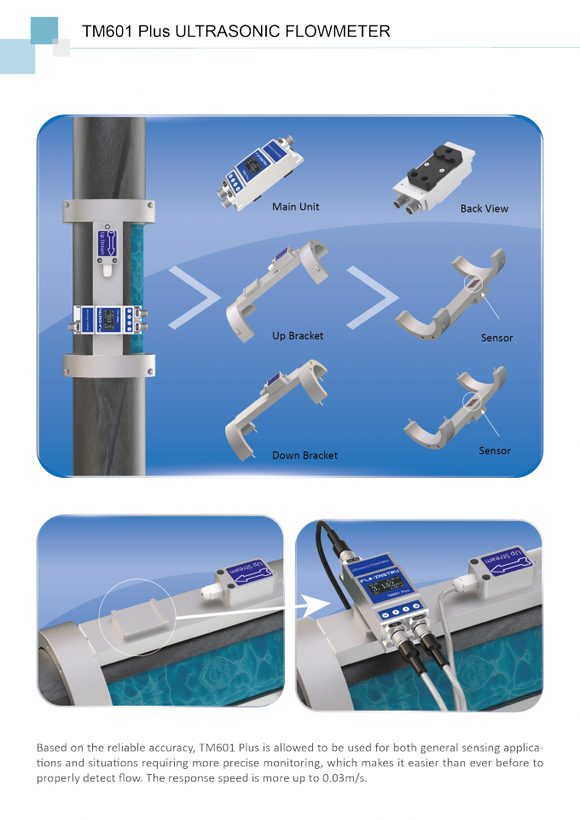

The TM601 Plus Clamp-On Ultrasonic Flowmeter is engineered specifically for ultrasonic cleaning systems that involve larger pipe diameters. Featuring a snap-on main unit and a non-intrusive clamp-on sensor design, the TM601 Plus enables tool-free installation in under 1 minute, without halting production or modifying the pipeline.

Its enhanced design allows precise flow measurement across a wide variety of pipe materials, including stainless steel, carbon steel, copper, PVC, PVDF, PPR, PPH, and HDPE. With an OLED display (128×64 px) for clear readings even in low-light environments, the TM601 Plus delivers performance and convenience in one compact package.

Key Features & Benefits:

-

Clamp-On, Non-Invasive Design:

No pipe cutting, no pressure loss, and no production downtime—installation is completely external. -

Snap-On Display Installation:

The main display unit features a built-in buckle system that clamps easily onto the bracket without tools or screws. -

Built for Bigger Pipes:

Includes an enlarged pipe clamp and bracket system designed to accommodate larger diameters with sensors positioned for optimal flow detection. -

Ultra-Fast Setup:

Get started in just 1 minute—perfect for time-sensitive installations. -

OLED Display Screen:

High-contrast 128×64 pixel screen ensures visibility in both bright and dark environments. -

Versatile Pipe Compatibility:

Suitable for a range of pipe materials including stainless steel, carbon steel, copper, PVC, PVDF, PPR, PPH, and HDPE.

Ideal For Use In:

-

Ultrasonic Cleaning Machines (Large Scale)

-

Industrial Washing & Rinsing Equipment

-

Process Equipment in Manufacturing Plants

-

Environments Requiring Fast, Non-Disruptive Installations

Specifications

| Velocity Rate | 0.328 ft/s~±16ft/s(0.1m/s~±5m/s) |

| Accuracy | ±2.0% |

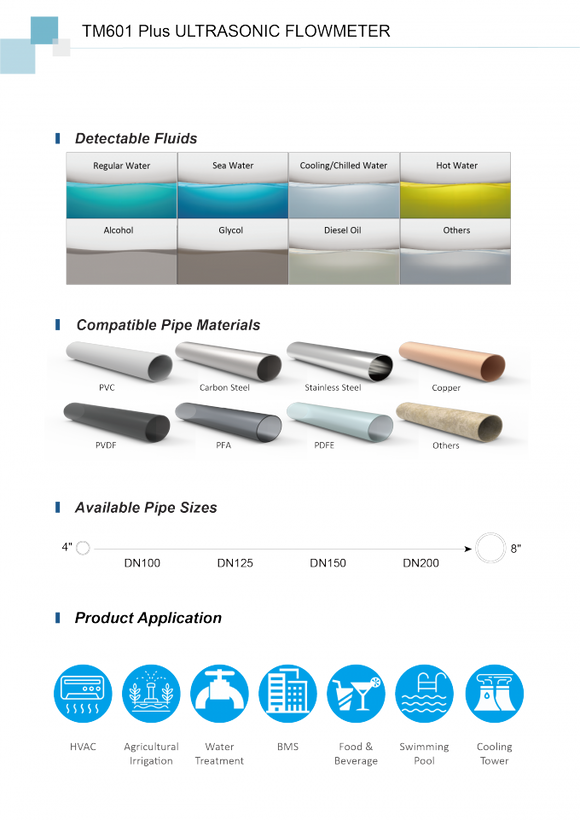

| Pipe Size | DN100 DN125 DN160 DN200 |

| Liquid | Regular water,sea water,cooling/hot water,alcohol.. |

| Pipe Material | PVC,stainless steel,carbon steel,copper.… |

| Power Supply | 9~36V DC,maximum 500mA |

| Communication | Support MODBUS protocol,RS485 |

| Analog Output | 4-20mA,Maximum 750Ω |

| Alarm Output | OCT upper and lower limit alarm function (optional) |

| Display | OLED 128*64 dot-matrix display screen |

| Key Panel | Four touch buttons |

| Flow Unit | Support metric unit selection,Cubic Meters(m³),Liters(l),USA Gallons(gal). |

| Time Unit | /hour,/min,The factory default unit is cubic meters per hour. |

| Daily,Monthly,and Annual Flow Totalizer | |

| Temperature | Ambient:14F~+122F(-10℃~+50℃) |

| Liquid:14F~+122F(-10℃~+50℃) | |

| Ambient Humidity | RH 0~95%,No condensation |

| Housing Material | Aluminum alloy,CNC machined processing |

| Protection Rate | IP54 |

| Cable Length | 6.6ft (2m)standard |

The Pipe Size Range and Flow Range Reference Table

| DN | OD | OD Range | Inch | Flow Range |

| DN100 | OD110 | 108mm-116mm | 4" | 2.917~145.858 m/h |

| 48.619~2430.963 l/min | ||||

| 12.844~642.194 gal/mir | ||||

| DN125 | OD140 | 132mm-142mm | 5" | 4.558~227.903 m³/h |

| 75.968~3798.380 I/min | ||||

| 20.069~1003.429 gal/min | ||||

| DN150 | OD160 | 158mm-168mm | 6" | 6.564~328.180 m³/h |

| 109.393~5469.666 l/min | ||||

| 28.889~1444.938 gal/min | ||||

| DN220 | OD220 | 218mm-228mm | 8" | 11.669~583.431 m³/h |

| 194.477~9723.852 I/min | ||||

| 51.376~2568.778 gal/min |

Product title

Vendor

R 19.99 | R 24.99

Product title

Vendor

R 19.99 | R 24.99

Product title

Vendor

R 19.99 | R 24.99

Product title

Vendor